Consulting, plant design, plant planning, measurement and test systems for exhaust gas and exhaust air purification systems

BIONIK – Engineering for biological, physical and chemical exhaust gas and exhaust air purification systems

Bionics works with competence and passion towards a clean future

WE WORK...

...WITH COMPETENCE

...AND PASSION

...TOWARDS A CLEAN FUTURE

...AND PASSION

...TOWARDS A CLEAN FUTURE

BIONIK advises on the selection and design of exhaust gas and exhaust air purification systems

CONSULTING

BIONIK supports its customers in all phases of the life cycle of a production plant with consulting and management services for technical tasks in the field of process gas and exhaust air purification.

• Requirements analysis: In close cooperation with the client, the specific requirements for exhaust air or process gas cleaning are determined. This may include raw gas analysis, required levels of purification, operating conditions and regulatory requirements. The customer's strategic considerations play an important role, as do the location of the plant and its integration into existing systems.

• Consultancy on technologies:Based on the specific requirements, BIONIK provides an overview of the available technologies and their advantages and disadvantages and carries out an initial feasibility assessment. This includes recommendations for specific processes and plant components that are best suited for the customer.

• Economic analysis:: In this context, BIONIK provides initial cost estimates and a rough overview of the economic efficiency of the planned measures. The aim of BIONIK's consulting services is to support the plant operator in making investment decisions.

• Environmental and legal advice:: The environmental regulations to be complied with and how the plant contributes to improving the sustainability of the production site are discussed.

• Plant optimisation:: BIONIK supports operators of exhaust air and waste gas cleaning systems with advice on optimising facilities when operating conditions change and on developing cost-optimised maintenance and servicing systems for efficient and safe operation.

BIONIK Expert for the conception, planning and optimization of exhaust gas and exhaust air purification systems

PLANT CONCEPTS

The development of the plant concept is the process in which BIONIK determines the basic structure and functionality of the plant. It forms the bridge between consulting services and detailed plant design.

The process of conceptual planning includes the following steps

• Establishment of fundamentals:This involves collecting and analysing all the relevant data and framework conditions. These include data on production processes that generate process gas or waste air, material flows, quantity and composition of pollutants, regulatory requirements, energy concepts, etc. Where available, customer data is used, and if necessary, BIONIK will carry out its own measurements.

• Process selection:Based on the results of the basic evaluation, the most suitable process for process gas or exhaust air cleaning is determined and the required key components are defined.

• Plant dimensioning:: The size of the main plant components and their capacities are determined. Factors such as the volume of process gas/exhaust air to be treated, the pollutant content and the required degree of treatment are taken into account. Even at this early stage, work begins on optimising the plant's energy consumption.

• Process integration:The planned system is usually integrated into existing production processes. This includes the design of the system's location, its connection to exhaust air ducts or gas piping, and the integration of the control system. Special attention is paid to the subsequent operating conditions and process stability concepts.

• Preliminary layout:The first rough layout of the plant is created, showing the general arrangement of the main components. Aspects such as space requirements, material flows and economic considerations are taken into account.

• Safety and environmental concept:In this phase, BIONIK develops initial safety concepts and measures for environmental and industrial safety.

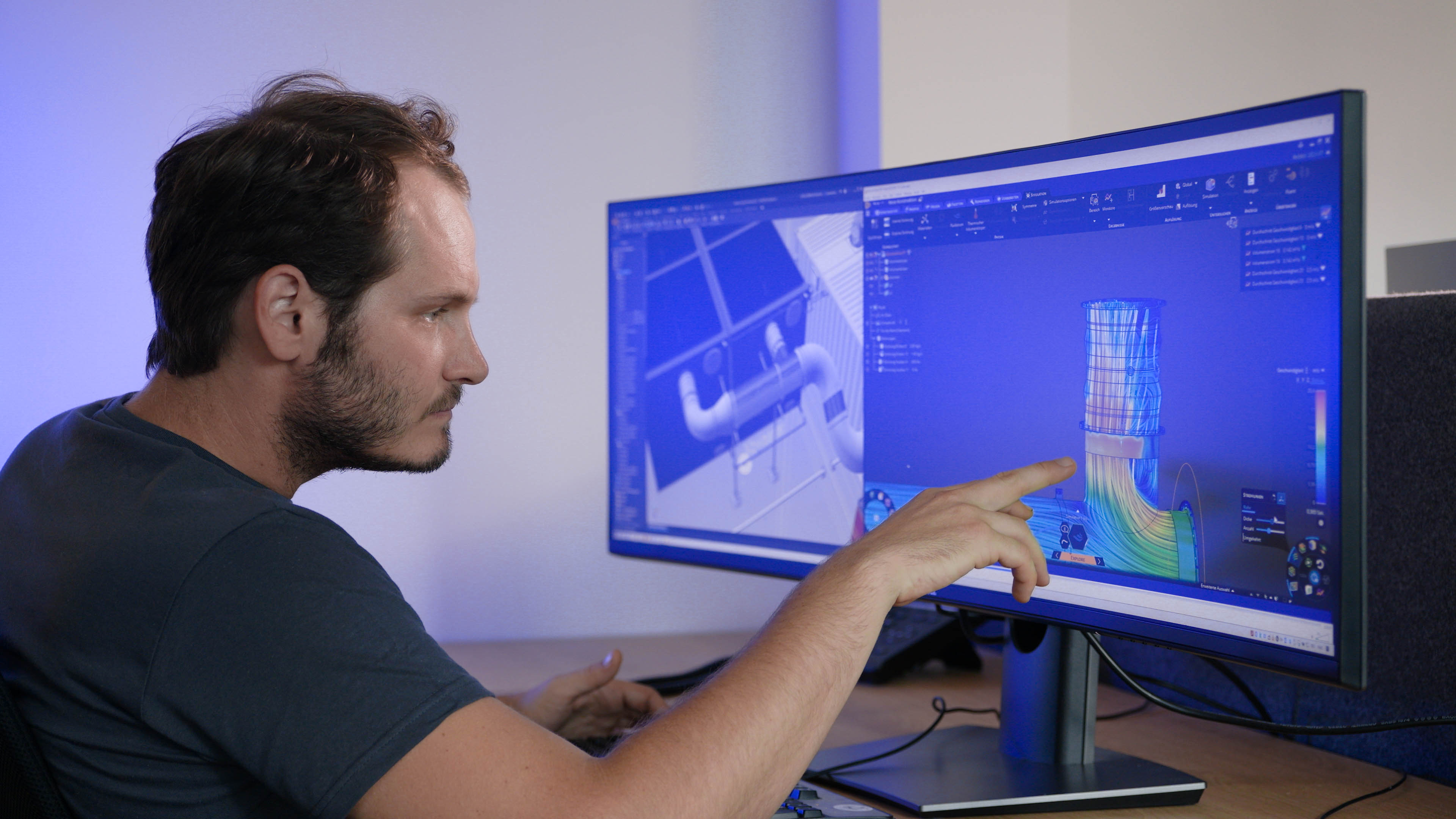

BIONIK supports plant planning with basic engineering, process simulation and optimization, detailed engineering, implementation of approval procedures, time and cost planning as well as planning of commissioning and plant optimization

PLANT DESIGN

BIONIK uses the results of the conceptual planning for the detailed design of the plant, considering the customer's requirements and the legal framework. With the planning results, BIONIK provides the basis for technically mature, safe and economical plants.

In detail, BIONIKs plant design includes all the necessary steps to prepare for plant construction:

• Basic Engineering:The basic design includes the preparation of technical drawings and the first detailed plans. This includes P&ID (Process and Instrumentation Diagrams), mass and energy balances and the design of the main components.

• Process simulation and optimisation:Simulation software is used to virtually test and optimise the planned processes. The aim is to ensure the efficient and safe operation of the plant.

• Detail Engineering:The execution planning includes the detailed and production-ready development of all plant components and their specifications. This includes material selection, mechanical design, piping planning, electrical and automation systems.

• Approval procedures:: BIONIK supports plant operators in all environmental and safety-related matters during the official approval process. Knowledge of and compliance with guidelines, standards and legal requirements play a central role here.

• Time schedule and cost planning:A detailed schedule for the construction and installation of the plant is developed. In addition, a list of operating resources is prepared, and an assessment of the expected investment and operating costs is made.

• Planning of plant commissioning and optimisation:After installation, the plant is commissioned, and test runs are carried out to ensure that the purification performance meets the requirements. As part of the plant optimisation, measures are taken to further optimise the use of operating materials and energy.

BIONIK develops customer-specific measurement programs for exhaust air and exhaust gas problems and carries out measurements to determine individual substances, odor concentration, total carbon content as well as particle, volume flow, humidity and temperature measurements

MEASUREMENT

More than 30 years of experience and an extensive range of measurement equipment enable BIONIK to provide a well-founded assessment of the technological task at hand when solving process gas and exhaust air tasks.

BIONIK develops customer-specific measurement programmes and carries out the necessary measurements, such as

• Olfactometry to determine the odour concentration

• FID measurement to determine total carbon content

• GC-MS analysis to determine individual substances

• Volume flow measurement

• Humidity and temperature measurement

• Particle measurement

• Measurement of specific pollutants

In addition to developing design principles for the construction of new gas treatment or air pollution control systems, accurate and reliable measurement results are used to improve the performance of existing systems with limited functionality or modified operating conditions.

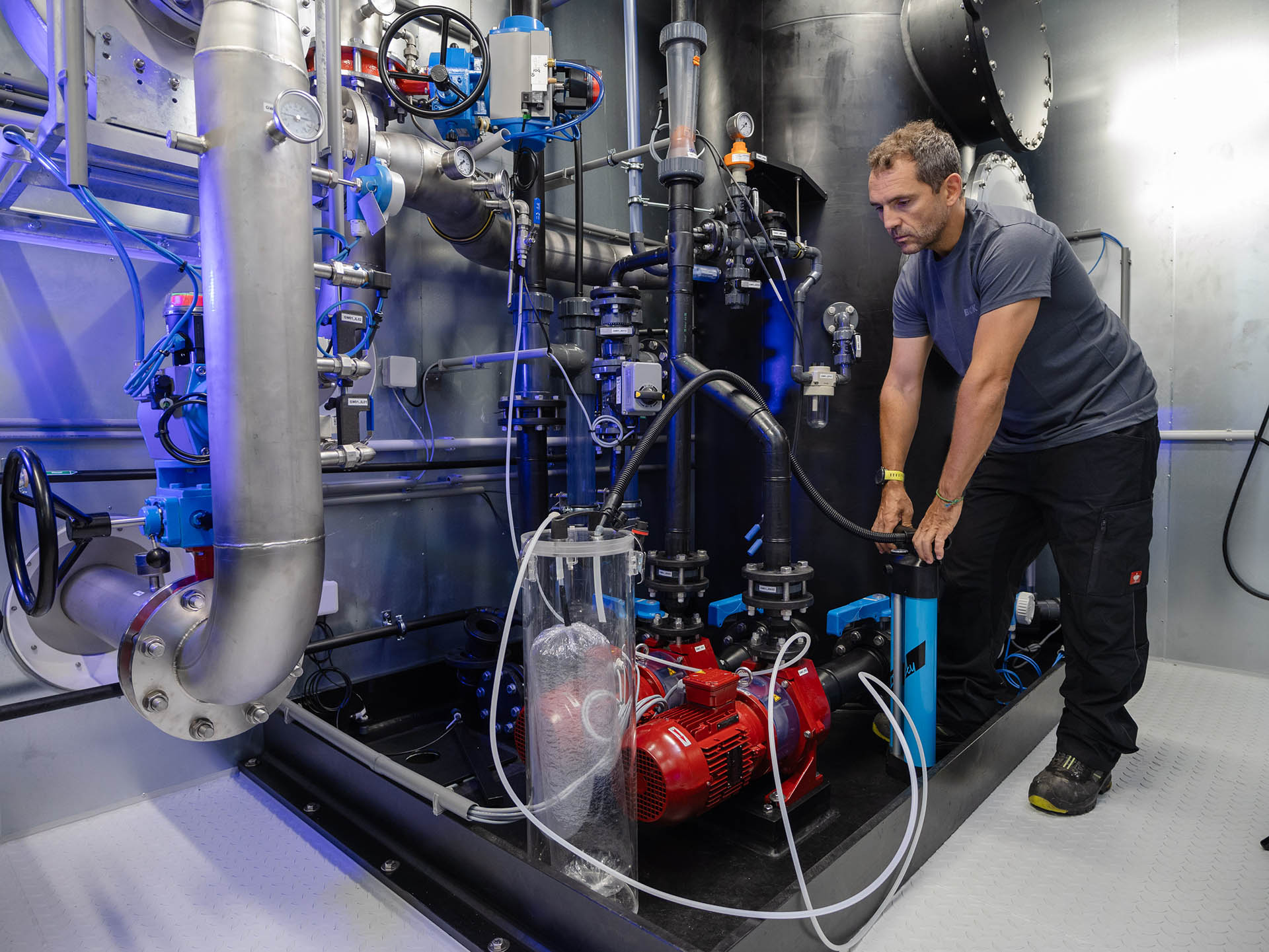

With its modular test systems, BIONIK offers the opportunity to test the functionality of a planned system in a field trial on a small scale at a manageable cost.

TEST FACILITIES

In waste gas and exhaust air cleaning, the design of a new plant can be made rather difficult by undefined substances in the raw gas, fluctuating flow rates, varying operating parameters and other imponderables.

Under such challenging conditions, BIONIK’s modular pilot plants offers the option of testing the operation of a planned system on a small scale and with manageable effort in field trials.

The pilot plant can be used to carry out test operations over a pre-defined period of time, checking all the essential parameters.

If it turns out that the test results do not meet expectations, components, modules and – in extreme cases – the entire process can be adapted in good time. The economic and technical risks of a new plant can thus be minimised.

-

BIONIK Filtersysteme GmbH

Katschberg Strasse 84

9851 Lieserbruecke

Austria

Tel.: +43 4762 44840

biofilter@bionik.at

www.bionik.at -

BIONIK Filtersysteme GmbH

Energiestrasse 2/2

2540 Bad Voeslau

Austria

Tel.: +43 4762 44840

biofilter@bionik.at

www.bionik.at -

BIONIK Filtersysteme GmbH

Tarragona 12

07011 Palma de Mallorca

Spain

Tel.: +34 617 37 42 67

biofilter@bionik.es

www.bionik.es -

BIONIK Filtersysteme Kft

Verő József u. 1

9400 Sopron

Hungary

Tel.: +36 70 4329818

biofilter@bionik.hu

www.bionik.hu -

LEGAL NOTICE

DATA PRIVACY